- Products >

- Automotive Belts >

- Raw Edge V-belts

Raw Edge V-belts

Flexible, fabric-free raw edge v-belts are used in the engines of automobiles, trucks, buses, and construction machinery. Ideal in harsh load fluctuation and high-temperature environments, these belts have excellent heat resistance, abrasion resistance, and deformation resistance.

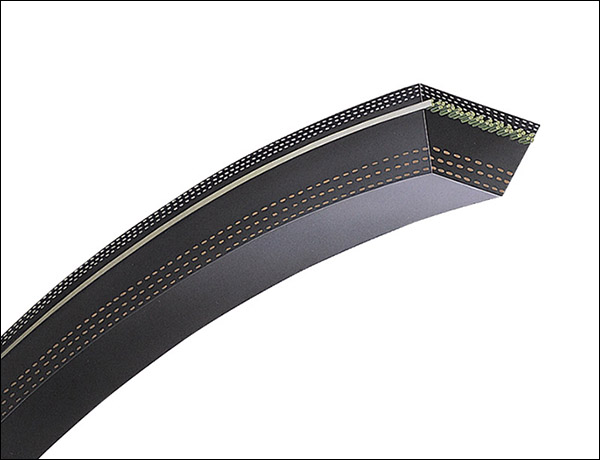

REMF

Raw Edge Plain V-belt

Direct exposure of special rubber to the pulley provides high friction force resulting in increased power transmission.

MPMF

Raw Edge Multi-ply V-belt

The structure of this belt is similar to that of the Raw Edge plain belt. However, this belt is designed to reduce noise by applying several fabric layers to the bottom surface.

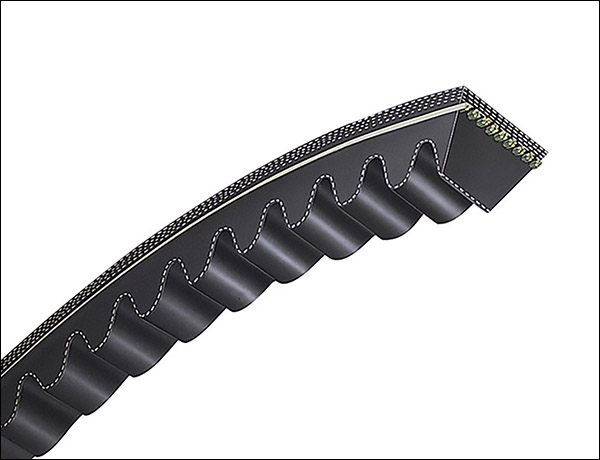

RECMF

Raw Edge Cogged V-belt

A cogged bottom belt structure reduces the energy loss caused by bending. As a result, it fits small pulleys and gives stable performance at high speeds.

web-1.jpg)

WCF

Wide Angle Cogged V-belt

Wider angle (52°) than the standard type. Cogged profile allows improvement of bending fatigue resistance.

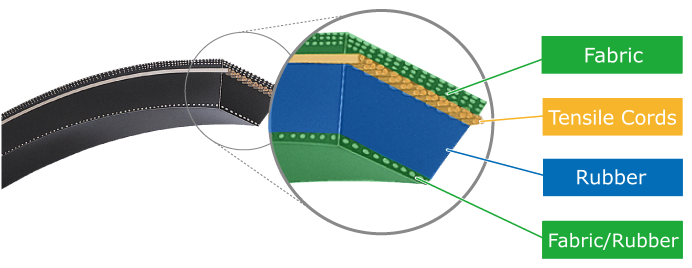

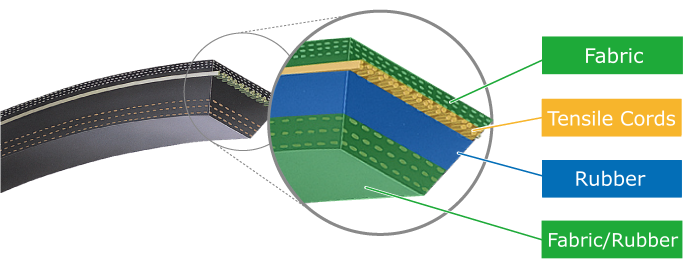

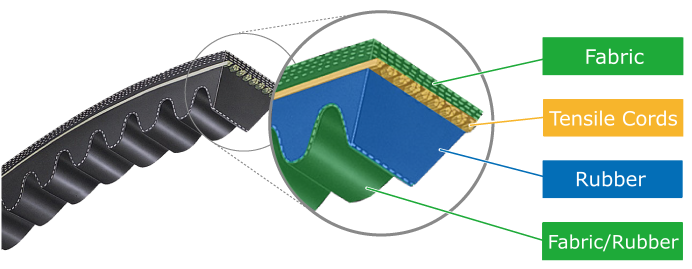

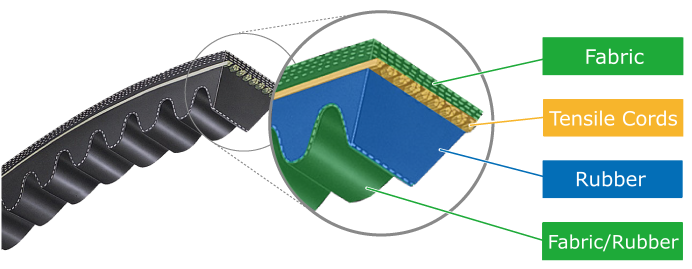

Construction

Top Fabric

Strong, wear-resistant bias cut fabric designed for protection without loss of flexibility.

Cords

High tensile strength, pre-stretched polyester cords for reduced stretching and constant tension.

Rubber

Reinforced with fiber chips to provide high coefficient of friction, wear resistance and greater flexibility. Insures a smooth and even transfer of load forces to the cords.

Bottom Fabric

Crack resistant, highly flexible fabric is impregnated with oil and heat resistant rubber compound. Laminated construction insures a strong bond and reduced noise.

Rubber Sides

Eliminates slip and maintains a positive contact with the pulley grooves for constant, reliable energy transfer.

The side of the belt has a rubber-exposed structure, which provides a large gripping force and high transmission capacity.

Constructed with multiple layers of fabric on the bottom. Prevents excessive gripping of the belt and pulleys and suppresses pronation.

Cog-shaped bottom of the belt improves flexibility. Longer service life.

Wider angle (52°) than the standard type. Cogged profile allows improvement of bending fatigue resistance.

Symptoms for Replacement

When you find any of the symptoms shown below, replace the belt. It is recommended that you replace the idling pulley and/or tensioning pulleys at the same time.

Questions?

Please contact us to request more information about our product and how it can work with your application.

Brochure

Explore the features and options our line-up of automotive belts has to offer to meet your needs.